Cargo Control System

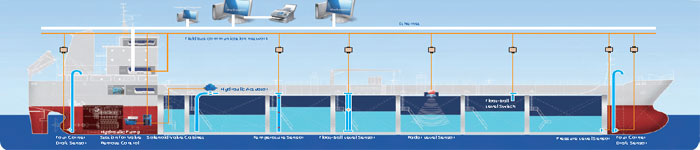

Cargo control system (CARGOPRO), which is one of the most important sub-systems in vessel automation, is used for vessel fourcorner draft checking, liquid cargo tank temperature measure and alarm, pressure alarm, cabin level display and alarm, valve remote control and valve position indication, cargo infall alarm, liquid cargo tank independent high level and overfill alarm and other measure, alarm and control function.

Our CargoPro adopts modularity electric package design. On the one hand,this system can work independently; on the other

hand, it can work with other systems by seamless connection, such as E/R monitor & alarm system and so on.

Our cargo control system consists mainly of the following three sub-systems:

1. Level Indication System 2. Valve Remote Control System

3. Cargo Ingress Alarm System(CARGOSAFE)

The internal communication between these subsystems is convenient.

These subsystems can work independently; at the same time, every subsystem can connect with others seamlessly according

to customer’s requirement.

Level Indication System (HMI)  Valve Remote Control System (HMI)  Cargo Ingress Alarm System (HMI) |

Liquid level indication system is used for relevant cabin level, temperature and four-corner draft measure and alarm. All signals are acquired by remote I/O installing at acquisition unit for accuracy. Remote I/O communicate with PLC control station at CCC for data exchange to realize remote control. HMI is for signal display and alarm message disposal. Valve Remote Control System consisted of PLC Control Station, SVU (Solenoid Valve Unit) including Emergency block, Remote I/O module, IPC, HPU (Hydraulic Pump Unit), Hydraulic Valve、Portable Pump、Emergency Portable Pump. Shut/Open operation is available at CCC. On-Off valve provides on/off indication, opening valve provides opening indication. Remote I/O module installed in SVP communicates with PLC control station for date transportation. The relevant electric valve will be powered up instantaneously and direction locked by PLC order for shut/open operation. The cargo hold level will be indicated by pressure level sensor, which converts the pressure signal into 4-20mA current signal and then send the current signal to independent compact PLC at CCC. PLC communicates with touch screen for alarm display and control. The whole system can realize independent level display, alarm and control. |